Yarn To Garments Manufacturing

Complete State of The Art Manufacturing For Spinning, Knitting, Knit Dyeing & Finishing, Printing & Garmenting.

Revenue

Company Has Annual Turnover of 80 Million USD.

Success

Growth Rate of 20% Annually Well Reputed & Sustainable Company Innovation & Deliverability With Satisfied Clients is Our Success.

KNOW OUR COMPANY

KNOW OUR COMPANY

3rd Generation Leed Textile & Apparel Conglomerate

Years Experience

We have started with the first spinning mill in Bangladesh and had extended into another spinning mill of 32700 spindles and built the forward linkage for knitting , knit dyeing , finishing , Yarn dyeing , garmenting and garment printing units . The capacity that we are able to produce on an yearly basis is 32 million pieces of knit apparels in the form of T-shirts , Polo shirts ,knitted bottoms ,knitted kids overalls ,knitted gowns ,sweaters ,sweat shirts .

We are a fully compliant manufacturing unit having sustainable systems and policies for supply chain management , production processes ,customer relations ,purchase, research & development ,environmental management and corporate social responsibilities .We are one of the fastest growing group in Bangladesh in the textile and apparel space willing to touch the lives of each individual in the planet and benefit through enhanced products and services.

View MoreKarooni Group bears the heritage of a family that has been involved in the trade of yarn, dyes & chemicals in Bangladesh for three generations. It entered into spinning industry in the sixties. At this stage the group is running with Shamsuddin Spinning Mills Ltd. (SSML) a 100% cotton yarn manufacturing unit, KNS Rotor Mills Limited (KRML) open end yarn manufacturing unit, Karooni Knit Composite Ltd. (KKCL) a knit composite unit, Karooni Fashions Ltd (KFL) a woven garments unit and Karooni Yarn Dyeing Ltd (KYDL).

KNOW OUR SERVICES

KNOW OUR SERVICES

Our Business Consulting Case Services

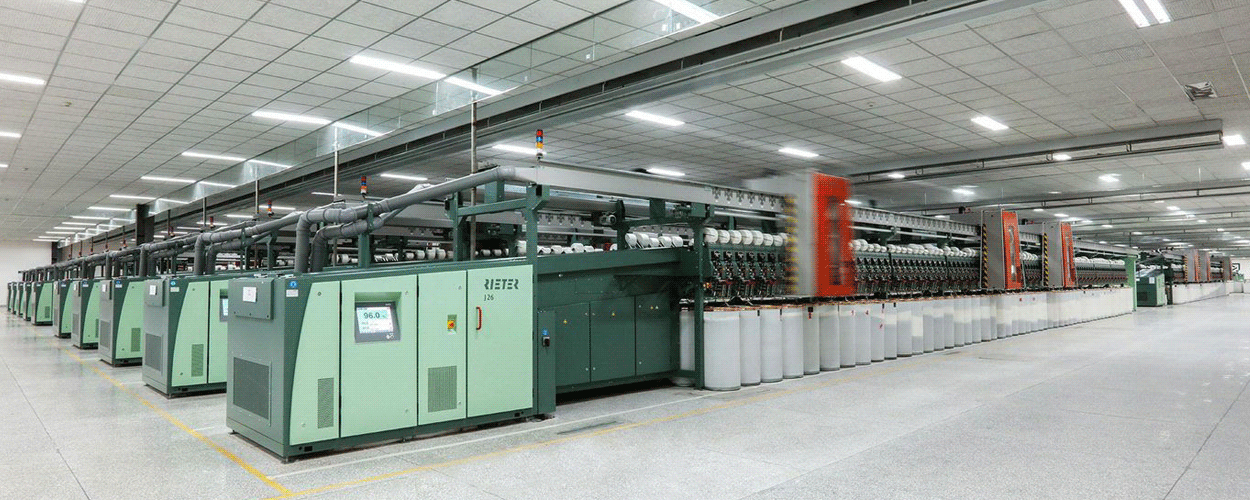

Spinning

The Shamsuddin Spinning Mills Limited (SSML) which went into operation in the nineties, located in the district of Gazipur, 50km from the capital. SSML is an 100% export oriented spinning unit having 32640 spindles. It has daily production capacity of 22000 kgs of carded and combed knit yarn of various count ranging from Ne 20s to Ne 40s and beyond depending on demands. The factory has world class machineries. Today SSML brand yarn remains a favorite with the knitters and our clients are eager to pay a premium price for our yarn. The SSML is ISO 9001-2008 certified and also possesses OEKO-TEX standard 100 certification along with GOTS and OCS by Control Union. It employs over 1100 workers, technicians and staffs

Knitting

We could not sit constended with the impressive success of SSML alone,the urge was more for vertical integration,that is,to convert our own quality yarn into magnificent end-products of knit garments.This led to the birth of Karooni knit composite Limited.which went into production in 2006 as a 100% export oriented knit composite unit. KKCL virtually consists of five dfferent units under one roof,These are :Knitting unit,Dyeing & Finshing unit(both tubular & and open width) and cutting $ sewing unit which produces the ultimate end product of knit garments.KKCL has it’s own printing and embroidary facilities.Besides,logistic and utility sections render integreted support services while our own power To meet the growing demends of a feet charging

Dyeing

Without yarn dyeing unit magnificent end product of knit and woven garments is incomplete. In this view the management of this group decided to establish such type of project, thus led to the birth of Karooni Yarn Dyeing Ltd. (KYDL), which started production in December 2017 to supply dyed yarn to 100% export oriented knit and woven fabrics industries. Its production capacity is 12,500 kg/day. In the KYDL state of the art brand new German machineries have been installed that enables to make different type of high quality and sophisticated yarn dyeing facilities. We also assembled capable managers, technical personnel and engaged skilled men for this new project.

Garments

We could not sit contended with the impressive success of SSML alone. The urge was more for vertical integration, that is, to convert our own quality yarn into magnificent end-products of knit garments. This led to the birth of Karooni Knit Composite Limited (KKCL) which went into production in 2006 as a 100% Export Oriented Knit Composite unit.KKCL virtually consists of five different units under one roof. These are: knitting unit, Dyeing & Finishing unit (both tubular & open width) and Cutting & Sewing unit which produces the ultimate end products of knit garments. KKCL has its own printing and embroidery facilities. Besides, logistics and utility sections render integrated support services while our own power generation unit ensures un interrupted supply of electricity.

Mission

We strive to attain our vision by practicing corporate governance, empowering and inspiring our associates, being transparent in our work process, continuously developing expertise, meeting & exceeding customer needs, demands & expectations, maintaining quality & consistency of our products & services, engaging with community, caring for environment and maintaining networks with our global partners.

Vision

We strive to attain our vision by practicing corporate governance, empowering and inspiring our associates, being transparent in our work process, continuously developing expertise, meeting & exceeding customer needs, demands & expectations, maintaining quality & consistency of our products & services, engaging with community, caring for environment and maintaining networks with our global partners.

Experience The Evolution Of Your Business

Karooni Group bears the heritage of a family that has been involved in the trade of yarn, dyes & chemicals in Bangladesh for three generations. It entered into spinning industry in the sixties. At this stage the group is running with Shamsuddin Spinning Mills Ltd. (SSML) a 100% cotton yarn manufacturing unit, KNS Rotor Mills Limited (KRML) open end yarn manufacturing unit, Karooni Knit Composite Ltd. (KKCL) a knit composite unit, Karooni Fashions Ltd (KFL) a woven garments unit and Karooni Yarn Dyeing Ltd (KYDL).

Call Us Everyday

+88022222294983Mail Us Anytime

kkcl@karooni.com BLOG & NEWS

BLOG & NEWS

Our Business Latest Blog & News

SUBSCRIBE TO OUR NEWSLETTER